Oil Water Separation

- Home

- Wastewater Treatment Plants

- Oil Water Separation

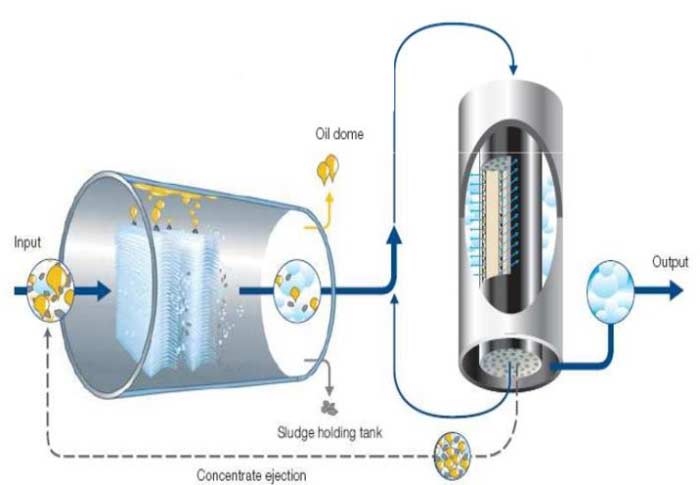

Ceramic Membrane Based Filtration System

At Inditron, we specialize in providing cutting-edge solutions to the most pressing challenges in liquid purification. Our commitment to innovation and excellence drives us to continually push the boundaries of technology, and one of our flagship offerings is ceramic membrane-based filtration technology.

Ceramic membrane-based filtration systems are advanced filtration technologies that utilize ceramic membranes for separating solids, colloids, and macromolecules from liquids. These membranes are typically composed of inorganic materials such as alumina, zirconia, titania, or silicon carbide.

Features of our Ceramic Membrane based Filtration Plants

Applications

Ceramic membrane-based filtration systems are used in various processes such as microfiltration, ultrafiltration, nanofiltration, and reverse osmosis, depending on the pore size of the membranes and the desired level of filtration. They offer efficient and reliable solutions for separating and purifying liquids in industrial processes while providing cost-effective and sustainable alternatives to conventional filtration methods.

With Inditron, you can trust that you’re partnering with experts who are dedicated to delivering the highest quality wastewater treatment solutions. Experience the power of ceramic membrane-based filtration technology and unlock a new level of efficiency and sustainability for your operations.